Machine guarding safety protects workers from dangerous machinery in Ontario workplaces. Every manufacturing facility and fabrication shop must follow provincial regulations. These rules protect employees from hazardous equipment in industrial establishments. Businesses that understand machine guarding safety avoid workplace injuries, penalties, and work stoppages. Klassen Custom Fabricating designs and installs machine guarding that meet Ontario’s safety standards.

Understanding Machine Guarding Safety Requirements

Ontario’s Occupational Health and Safety Act sets clear rules for machine guarding. The Industrial Establishments Regulation (Regulation 851) provides specific requirements for Safeguarding of Machinery. These regulations apply to all industrial establishments with operating machinery. This includes small fabrication shops and large manufacturing plants. The law requires employers to protect workers from exposed moving parts, pinch points, rotating components, and other machine hazards.

Without proper protective elements, workers face serious injuries. Caught clothing can pull workers into machinery. Flying debris can cause eye injuries. Rotating parts can crush fingers and hands. These accidents result in lost time, medical costs, and regulatory fines.

Employers must identify all potential hazards before starting machinery. Risk Assessments help determine appropriate safeguarding devices for each situation. This prevents workplace injuries. Modern safety standards update regularly as new equipment enters manufacturing environments. Companies must stay current with these changes to maintain compliance and worker safety.

Core Guarding Requirements in Ontario

Protection Standards

Section 24 and Section 25 of Regulation 851 specify how protective elements must stop workers from touching dangerous moving parts. This includes rotating shafts, belt drives, chain drives, and mechanisms that catch clothing or body parts. Protective devices also protect workers from flying materials and waste stock.

Common hazards that require guarding include:

- Power transmission equipment like belts and pulleys

- Point of operation on cutting and forming machines

- Rotating parts such as shafts and gears

- Flying chips and sparks from grinding operations

Ontario law requires protective elements to block complete access to hazardous areas. Partial guards that allow hand or finger access fail to meet standards. A gap of even a few inches can allow contact with moving parts. Guards must work with how employees actually use equipment, not just how they should use it. This means considering reach distance, work posture, and tool access.

Material and Construction Standards

Section 26 outlines requirements for protective element construction. Guards must be strong and durable. They resist impact, vibration, corrosion, and daily wear. Each protective element must attach securely so workers cannot remove them easily. However, authorized workers need access for maintenance and repairs. Everything is outlined in Ontario’s Safeguarding of Machinery online.

Common materials for protective elements include:

- Steel plate for high-impact applications

- Expanded metal for visibility with protection

- Wire mesh for ventilation requirements

- Polycarbonate for transparent viewing needs

- Aluminum for lighter weight applications

Pre-Start Health and Safety Review Requirements

Ontario requires a Pre-Start Health and Safety Review (PHSR) for certain machinery. This applies to new equipment, modified machinery, and relocated equipment. The PHSR confirms the machinery meets safety standards before anyone uses it. The review examines protective elements and hazardous energy control systems.

A qualified professional engineer completes the PHSR. The engineer checks that guards meet requirements and work properly. Companies must keep PHSR documentation for Ministry of Labour inspectors.

Skipping the PHSR creates problems. Inspectors can shut down operations until reviews are complete. The cost of delayed production exceeds the cost of proper reviews. Smart companies plan PHSR into equipment schedules.

Companies must complete PHSR for older equipment that never received initial review. The same standards apply to old and new equipment. The goal is simple: verify guards protect workers before operation starts.

Worker Training Requirements for Machine Safety

Ontario requires specific training for each machine workers operate under Section 32 of the Industrial Establishments Regulation. General safety training is not enough. Workers need to know the specific hazards of their equipment.

Initial training covers three key areas:

- How to identify hazards on the machine

- How to operate safeguarding devices correctly

- What to do when protective elements are damaged or missing

Maintenance workers need annual training. They work differently than operators because they remove or bypass protective elements and work with hazardous energy. Training must cover lockout procedures and proper use of personal protective equipment. Training records must stay in employee files. These records prove compliance during inspections.

Professional Machine Guarding Solutions

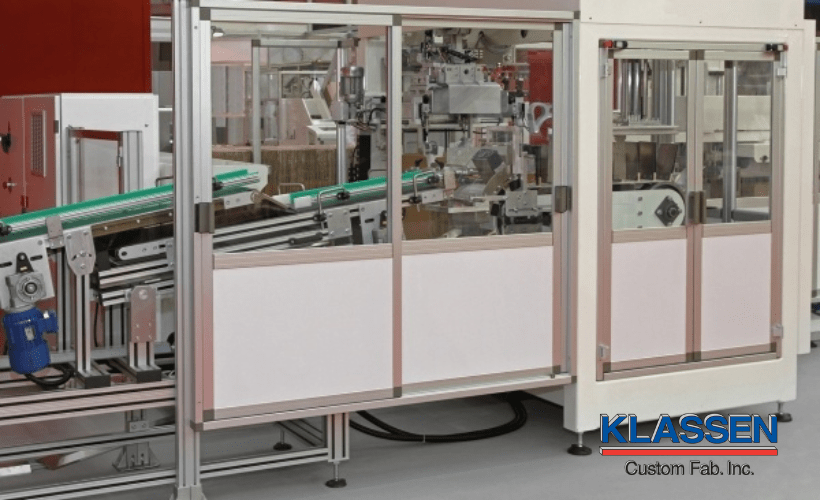

Custom machine guards work better than standard products. Klassen Custom Fabricating designs custom machine guards for specific industries and workspace needs. Custom fabrication solves problems that standard guards cannot fix.

Every facility has unique challenges. Floor space may be limited. Equipment may have unusual configurations. Custom guards address these specific situations and work with existing workflows.

Professional fabricators balance safety with productivity. These metal guards protect workers without slowing down work. Fabricators choose materials based on hazards, environment, and maintenance needs. Steel provides strength for heavy impacts. Polycarbonate allows visibility. Expanded metal combines protection with airflow.

Proper installation keeps guards working correctly for years. Professional installers understand mounting techniques, proper fasteners, and structural requirements.

Types of Safeguarding of Machinery and Their Applications

Fixed Guards

Fixed guards stay permanently in place. They attach to the machine frame or nearby structures. Workers need tools to remove them. This prevents easy bypassing. Fixed guards work best when workers never need access during normal operation.

Many manufacturing operations prefer fixed guards. They are simple and reliable. Once installed correctly, they need little maintenance. Fixed guards have no moving parts to wear out or adjust. This makes them ideal for protecting drive belts, gears, and other components that only need access during scheduled maintenance.

Adjustable Guards

Some machinery needs different guard positions for different jobs. Adjustable guards solve this problem while keeping workers safe. The adjustment mechanism must be secure. It should not move accidentally but allow authorized changes.

Material processing equipment often uses adjustable guards. Workers change guard positions based on material size. Training ensures workers adjust guards correctly for each job.

Interlocking Guards and Light Curtains

Interlocking guards connect to machine controls. When someone opens the guard, the machine stops automatically. This prevents operation while the guard is open. A light curtain serves as an invisible protective element that stops machinery when the beam is broken. Interlocking guards and light curtain systems provide the highest protection level for areas workers access frequently.

The interlock must be fail-safe. If something breaks, it defaults to the safe position. Regular testing confirms interlocks work correctly. Bypassing interlock systems violates safety laws and creates extreme danger.

Compliance and Enforcement in Ontario

The Ministry of Labour enforces machine guarding rules through workplace inspections. Inspectors can enter facilities without notice. They check guards, review paperwork, and interview workers. Inspections focus on actual workplace conditions, not just documentation.

Violations result in orders to fix problems. Orders may stop work until fixes are complete. This creates immediate production loss. Serious violations lead to large fines. Corporations can face fines of hundreds of thousands of dollars. Supervisors and directors may face personal liability for safety failures.

Following rules proactively is better than reacting to violations. Companies with proper guards avoid disruption and expense. Regular internal checks find problems before inspectors arrive. Many companies conduct monthly guard inspections. They document these inspections to show due diligence.

Ensuring Long-Term Machine Guarding Safety

Machine guarding safety requirements in Ontario needs ongoing attention. Guards need regular inspection to stay effective. Impacts, wear, and environmental factors damage protective features. Risk reduction depends on maintaining protective elements in good condition.

Maintenance schedules should include guard inspection. Workers who see damaged or missing guards must report them immediately. Clear reporting processes and quick responses maintain protection.

As machinery ages or processes change, guard needs may change. Regular reassessment keeps guards appropriate for current work conditions.

Partner With Expert Fabricators for Superior Protection

Klassen Custom Fabricating delivers machine guarding solutions that exceed Ontario’s safety requirements. The company works with steel, aluminum, and stainless steel to create guards that protect workers and support operations. Their ISO 9001 certification proves commitment to quality.

Located in Windsor, Ontario, Klassen Custom Fabricating serves industrial clients across the region. Services include custom electrical enclosures, machine guarding systems, and structural fabrication. The experienced team understands both machine guarding safety requirements and practical manufacturing needs. Contact Klassen Custom Fabricating today to discuss your machine guarding requirements and meet Ontario’s safety standards.

Share This Article

Choose Your Platform: Facebook Twitter Google Plus Linkedin