Finding the right fabrication shop Windsor businesses can trust requires a partner who delivers precision, quality, and reliability. Klassen Custom Fabricating provides comprehensive metal fabrication services to manufacturers, commercial builders, and industrial companies across Windsor-Essex County, Ontario, and throughout Canada and North America. Our ISO 9001 certified facility combines advanced technology, CNC machining capabilities, and expert craftsmanship to create custom solutions that meet your exact specifications.

Professional Metal Fabrication Services in Windsor

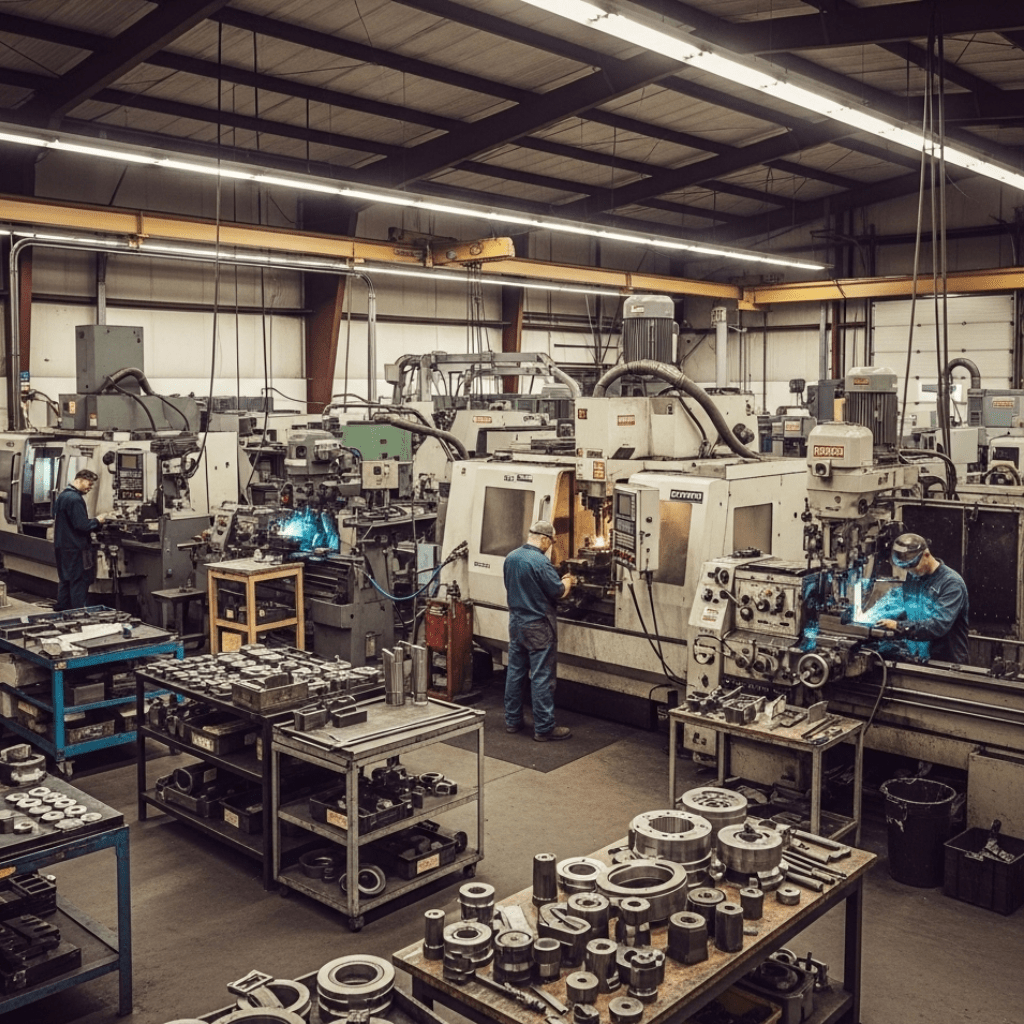

Klassen Custom Fabricating operates as a full-service metal fabrication company with decades of experience serving Windsor’s industrial sector. Our Manufacturing Capabilities encompass projects from initial design through final installation, ensuring every component meets strict quality standards. We work with steel, aluminum, stainless steel, and sheet metal materials to create products that perform reliably in demanding environments.

Our fabrication services include custom welding, CNC machining, cutting, forming, and assembly operations. Each project receives individual attention from our skilled technicians who understand the unique requirements of different industries. We maintain strict quality control procedures throughout every stage of production to deliver consistent results that exceed customer expectations.

The facility features modern equipment and organized workflows that enable efficient production schedules. Our team coordinates closely with clients to establish realistic timelines and provide regular project updates. This approach helps businesses plan their operations while ensuring fabricated components arrive when needed.

Custom Steel and Aluminum Fabrication Solutions

Klassen Custom Fabricating specializes in creating custom metal products that solve specific operational challenges. Our engineering team works directly with clients to develop practical solutions that improve efficiency and safety through precision CNC machining and custom machining processes. We analyze project requirements carefully to recommend optimal materials and fabrication methods.

Steel fabrication projects range from structural components to specialized industrial equipment. Our welders hold current certifications and follow established procedures to ensure strong, durable joints. We test completed weldments to verify they meet specified load requirements and safety standards.

Aluminum fabrication requires specialized techniques due to the material’s unique properties. Our team uses appropriate welding processes and heat treatments to maintain aluminum’s strength and corrosion resistance. This expertise enables us to create lightweight yet strong components for various applications.

Stainless steel projects demand precise handling to preserve the material’s appearance and corrosion resistance. We use dedicated tools and work areas to prevent contamination that could compromise stainless steel’s performance. Our finishing processes restore the material’s original appearance after fabrication.

Electrical Enclosures and Machine Guarding

Klassen Custom Fabricating manufactures electrical enclosures that protect sensitive equipment from environmental hazards. Our enclosures feature robust one-piece construction that provides superior durability compared to assembled alternatives. We build to CSA and UL standards to ensure compliance with electrical codes.

Custom electrical enclosures accommodate specific equipment layouts and access requirements. Our design team creates enclosures with properly sized openings, mounting provisions, and ventilation features. We include gaskets and sealing systems to maintain appropriate environmental protection ratings.

Machine guarding systems protect workers while allowing efficient equipment operation. Our guards incorporate lift and turn door mechanisms that provide reliable access control. These systems feature simple operation and dependable locking mechanisms that enhance workplace safety.

Safety guarding designs consider both protection requirements and maintenance access needs. We create guards that allow necessary equipment service while preventing accidental contact with moving parts. Our designs comply with current safety standards and industry best practices.

Welding and Assembly Services

Professional welding services form the foundation of quality metal fabrication. Klassen Custom Fabricating employs certified welders who work with various materials and welding processes, complemented by our advanced CNC machining operations. Our team selects appropriate welding methods based on material type, thickness, and application requirements.

Structural welding projects require precise joint preparation and proper welding procedures. Our welders follow established welding procedure specifications that ensure consistent quality and strength. We perform visual inspections and testing to verify weld integrity before project completion.

Assembly services combine multiple fabricated components into finished products. Our assembly area provides adequate space and equipment for handling large structural items. We use precision measurement tools to ensure proper alignment and fit during assembly operations.

Complex assemblies require careful planning and coordination between fabrication and assembly teams. We develop assembly sequences that maximize efficiency while maintaining quality standards. Our project managers coordinate material flow to prevent delays and ensure smooth production.

Advanced Fabrication Technologies and Capabilities

Klassen Custom Fabricating invests in modern equipment that enables precise, efficient fabrication operations. Our technology portfolio includes computer-controlled cutting systems, CNC machining centers, forming equipment, and welding stations. These tools help us maintain consistent quality while meeting demanding production schedules.

Our facility layout supports efficient material flow from receiving through shipping. We organize work areas to minimize handling and reduce production time. This systematic approach helps control costs while maintaining quality standards that satisfy demanding customers.

Quality control procedures include incoming material inspection, in-process monitoring, and final product verification. We maintain detailed records of all quality checks to ensure traceability and continuous improvement. Our quality system supports ISO 9001 certification requirements.

Laser Cutting and CNC Machining Precision

Laser cutting technology provides exceptional accuracy for complex shapes and tight tolerances. Klassen Custom Fabricating operates advanced laser cutting systems that handle various material types and thicknesses. Our programming team optimizes cutting paths to minimize material waste and reduce production time.

CNC machining capabilities include drilling, tapping, milling, and forming operations that create accurate features in fabricated components. We use computer-controlled CNC machining equipment to maintain consistent dimensions across multiple parts. This precision ensures proper fit and function in final assemblies.

Our CNC machining services extend to complex geometries and tight tolerance requirements that traditional fabrication methods cannot achieve. Advanced CNC machining technology enables us to create intricate parts with exceptional accuracy and repeatability.

Material optimization software helps reduce waste by efficiently arranging parts on raw material sheets. Our operators review cutting programs to identify opportunities for improved efficiency. This attention to detail helps control material costs and supports competitive pricing.

Paint and Powder Coating Finishes

Surface preparation and finishing services protect fabricated components from corrosion and wear. Klassen Custom Fabricating provides comprehensive finishing services including cleaning, priming, painting, and powder coating. Our finish options range from basic protection to decorative colors that enhance product appearance.

Powder coating applications provide durable, attractive finishes that resist chipping and fading. Our powder coating booth maintains controlled temperature and humidity conditions for optimal finish quality. We offer various colors and textures to match customer specifications.

Paint systems include primer and topcoat applications that provide long-term protection in harsh environments. Our paint booth features proper ventilation and temperature control for consistent results. We select paint systems based on environmental exposure and performance requirements.

Surface preparation procedures remove contaminants and create proper adhesion for finish coatings. We use appropriate cleaning methods and abrasive techniques to prepare surfaces for finishing. This preparation ensures maximum coating life and performance.

Industries Served by Windsor Fabrication Experts

Klassen Custom Fabricating serves diverse industries that require custom metal fabrication solutions. Manufacturing companies rely on our expertise for production equipment, fixtures, and structural components. We understand manufacturing requirements and create solutions that improve productivity and safety.

Commercial construction projects benefit from our structural fabrication capabilities. We create steel frames, platforms, and architectural elements that meet building code requirements. Our team coordinates with construction schedules to deliver components when needed for installation.

Automotive industry clients require precision fabrication for tooling, fixtures, and production equipment. Klassen Custom Fabricating understands automotive quality standards and delivery requirements, utilizing advanced CNC machining to meet exact specifications. We create solutions that support efficient vehicle production and assembly operations.

Industrial facilities need reliable equipment and structural components that operate safely under demanding conditions. Our fabrication expertise helps industrial companies maintain productive operations while meeting safety regulations. We create solutions that reduce maintenance requirements and extend equipment life.

Quality Standards and ISO Certification

Klassen Custom Fabricating maintains ISO 9001 certification that demonstrates our commitment to quality management principles. Our quality system includes documented procedures, regular audits, and continuous improvement activities. This systematic approach ensures consistent quality across all projects and customers.

Quality control procedures begin with incoming material inspection and continue through final product testing. We maintain calibrated measuring equipment and trained inspection personnel to verify dimensional accuracy and material properties. Our quality records provide complete traceability for all fabricated components.

Customer satisfaction drives our quality improvement efforts. We collect feedback from customers and use this information to identify opportunities for enhanced service delivery. Regular quality reviews help us maintain high standards while adapting to changing customer needs.

Continuous training programs keep our team current with industry best practices and safety requirements. We invest in employee development to maintain the skills necessary for quality fabrication work. This commitment to training supports consistent performance and customer satisfaction.

Partner with Windsor’s Leading Fabrication Specialists

When your project demands precision, reliability, and expert craftsmanship, Klassen Custom Fabricating delivers the fabrication shop Windsor companies choose for their most critical applications. Our comprehensive services, advanced technology, and commitment to quality make us the ideal partner for your next manufacturing or construction project.

Contact Klassen Custom Fabricating today to discuss your fabrication requirements and discover how our expertise can bring your vision to reality.

Share This Article

Choose Your Platform: Facebook Twitter Google Plus Linkedin