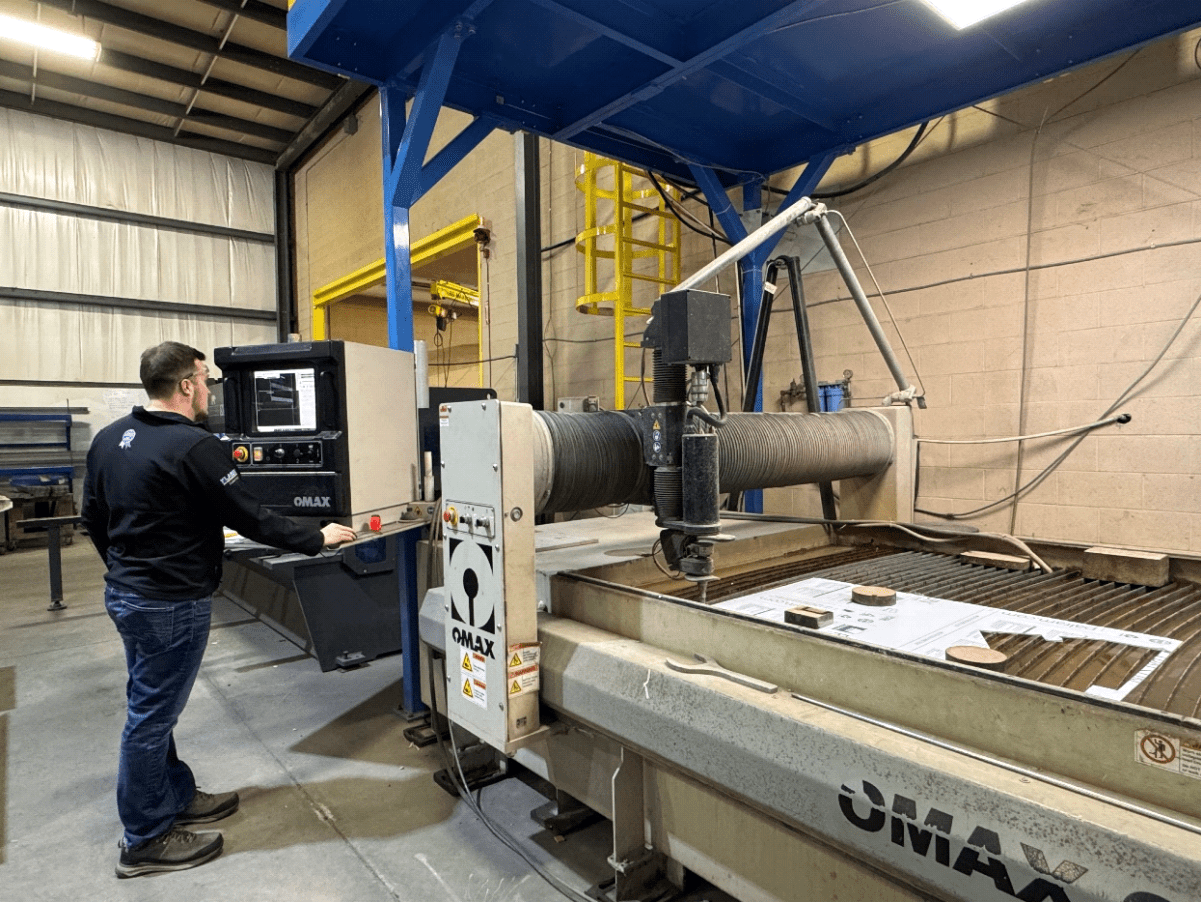

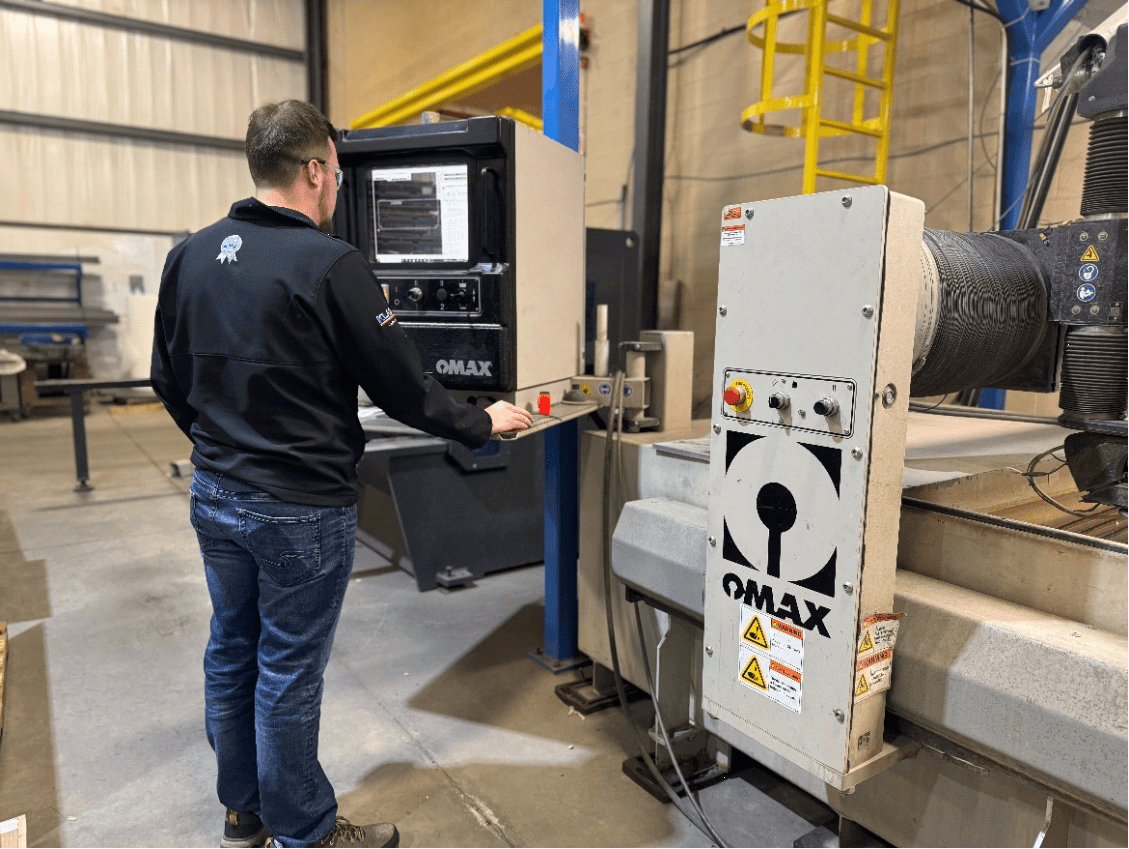

Water Jet Cutting

The process begins with a high-pressure water pump that pressurizes water to extremely high levels. An abrasive is selected based on the material being cut. This mixture of water and abrasive is then forced through a nozzle, creating a narrow, focused jet. The jet is directed against the material to be cut. Utilizing its integrated CNC system, the jet can be maneuvered to achieve precise cuts according to a pre-programmed design. As the waterjet works through the material, the eroded material is flushed away by the water, preventing any buildup and ensuring a clean cut. After cutting, the edges may require additional finishing depending on the application; however, waterjet cutting typically yields smooth edges and a minimal heat-affected zone, preserving the integrity of the materials.